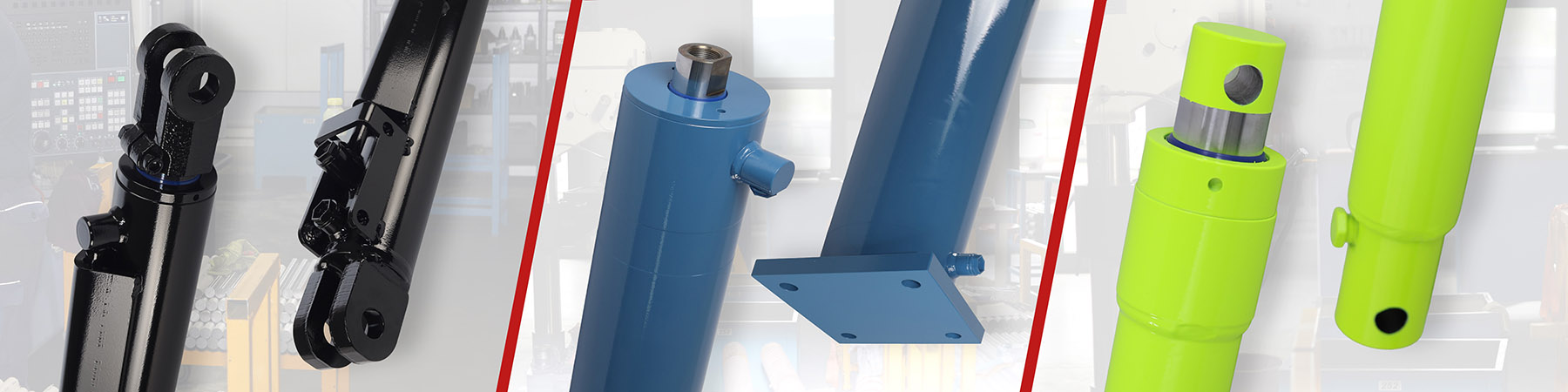

Design

Our process begins with collaborative design. Using advanced CAD software, our engineering team translates your performance requirements, spatial constraints, and application challenges into a precise digital blueprint. We focus on integrity, functionality, and efficiency, ensuring the final product is not just a component, but a perfectly integrated solution for your machinery.